Most of us spend more time indoors than we realise, in fact, on average, we are only outside for 10% of our lives.

The rest of the time we’re living and working indoors. If you stop to think about your average day, unless you have a job in the great outdoors like a conservationist, gardener or farmer, then you’re inside pretty much 90% of the time.

It’s not just our working lives that are spent in buildings, our leisure time is too. By day we might be in offices, warehouses, manufacturing plants, schools, cafés and retail environments and in the evenings, restaurants, theatres, sports complexes, shopping centres and cinemas.

Or if you’re reading this and about to travel for work or a holiday, you’re probably inside an airport or another sort of travel terminus.

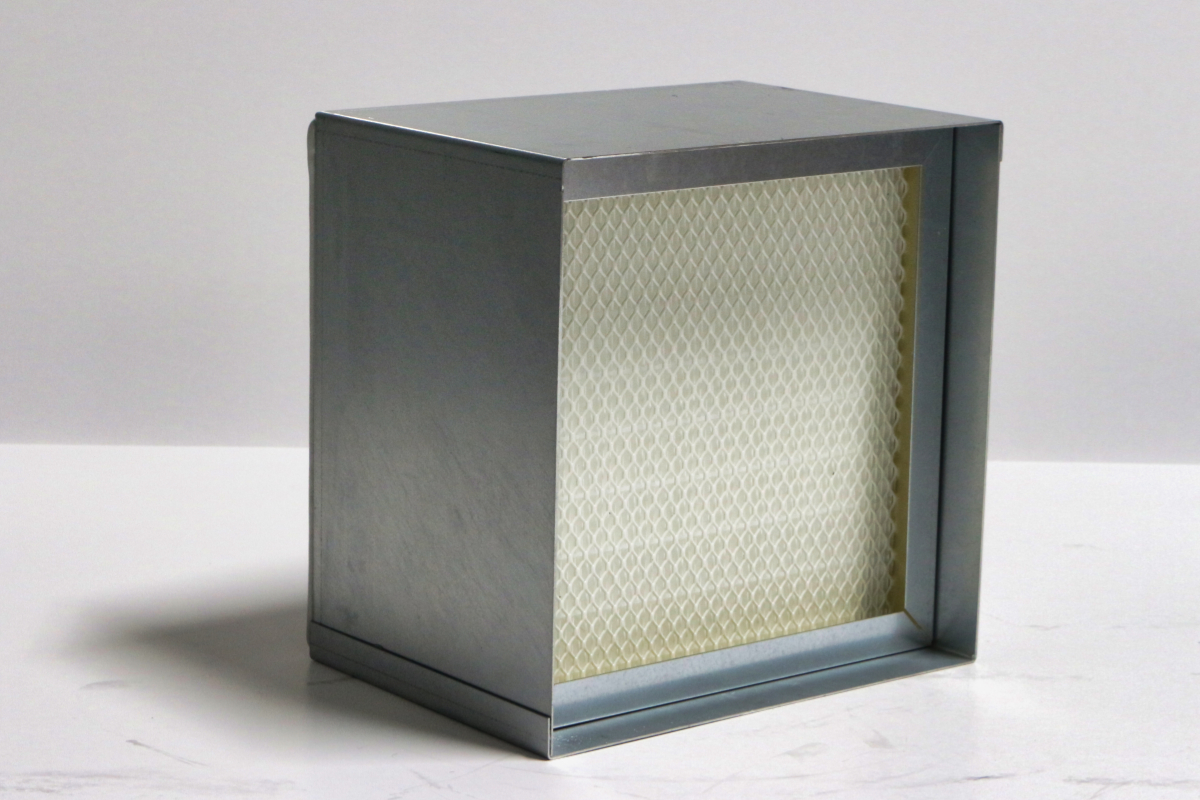

This is why we all need air filtration. Our world is an indoor one for most of our lives and, therefore, it’s crucial we all have clean air while indoors. It’s particularly important for vulnerable groups such as babies, children, the elderly and those who have health issues, which increasingly is every sector of the population.

How air quality effects your health

Many studies have shown a relationship between our health and indoor air quality (IAQ). They have also proven that particulate matter (PM) impacts on us and our wellbeing more than any other form of pollutant.

What is PM?

They are:

• Sulphate

• Nitrates

• Ammonia

• sodium chloride

• black carbon

• mineral dust

• combustion particles

• water.

PM is made up of a multifaceted mix of solid and liquid particles of both organic and inorganic substances suspended in the air.

How PM impacts on health

The effects of particulate matter on human health have been extensively studied in the past. The results are that fine dust can be a serious health hazard.

The most important diseases which have been associated with (caused or aggravated by) indoor air exposures due to PM contamination are:

• Allergy & Asthma

• Lung cancer

• Cardiovascular diseases (CVD)

• Chronic obstructive lung disease (COPD)

• Dementia

Why particle size matters

Size is important when it comes to particles and how they impact on your health.

There’s evidence to suggest particle sizes affect us differently:

PM10

Particles 10 µm in diameter or smaller can reach the respiratory ducts, potentially causing reduced lung function.

PM2.5

Particles 2.5 µm in diameter or smaller can penetrate the lungs and cause issues with lung functionality, as well as skin and eye problems.

PM1

Particles 1 µm in diameter or smaller can enter the bloodstream, because of their size, and are the most dangerous. These can cause cardiovascular diseases, dementia and cancer.

How to protect your team/customers

To protect yourself, your team and/or your customers. Get our professional help today. We are just a phone call or email away and our experts are here during normal working hours to assist you.

Get in touch

If you’d like to find out more about the air filters and services we offer and would like some free, friendly, advice, please contact us . There’s no obligation to buy from us.

The facts and information for this article were supplied by and with thanks to Eurovent AISBL / IVZW / INPA (2022). Eurovent 4/23 - 2022 - Selection of EN ISO 16890 rated air filter classes - Fourth edition. Brussels: Eurovent ©.